As technology advances, the protection of sensitive electronic components has become more crucial than ever, leading to an increased demand for effective packaging solutions. One essential product that has emerged in this regard is the anti static bag. These bags are specifically designed to shield electronic devices from static electricity, a phenomenon that can cause irreversible damage to delicate components. In the ever-evolving landscape of electronics, choosing the right anti static bag is vital for both manufacturers and consumers alike.

In this guide, we aim to provide you with comprehensive insights into selecting the best anti static bag tailored to your specific needs. From understanding the different types and materials used, to evaluating performance characteristics and usability, we will break down all necessary factors that contribute to the effectiveness of anti static bags. By the end of this guide, you will be equipped with the knowledge to make informed decisions, ensuring the safety and longevity of your electronic assets while navigating the complexities of the market.

Anti-static bags are essential in the electronics industry for protecting sensitive components from static electricity damage. Understanding the various types and materials of anti-static bags is crucial for selecting the right option for specific needs. Primarily, these bags can be categorized into two main types: conduction and static dissipative. Conductive bags, typically made from metals or carbon-loaded polymers, provide a pathway for static charges to dissipate. They are ideal for high-risk environments, where electronic components, such as microchips and circuit boards, require maximum protection. According to a 2022 study from the Electronic Industries Alliance, improper handling of static-sensitive devices can lead to financial losses exceeding $5 billion annually in the electronics sector.

On the other hand, static dissipative bags are made from materials that allow for some charge dissipation while still providing a certain level of insulation. These are suitable for environments where static discharge risk is moderate. Materials such as polyethylene and polypropylene, often treated with anti-static additives, fall into this category. The choice between these bag types should also consider the particular application, as certain processes might be more susceptible to static discharge. Industry research indicates that selecting the appropriate anti-static packaging can reduce the incidence of damage by up to 80%, underscoring the importance of informed decision-making in the procurement process.

When selecting an anti-static bag, understanding the key features is crucial to ensure the protection of sensitive electronic components. One of the primary characteristics to consider is the bag's material. Anti-static bags are typically made from polyethylene or a combination of materials that generate a faraday cage effect, effectively preventing static charge buildup. This protects delicate parts from electrostatic discharge (ESD) that can lead to component failure.

Another essential feature is the bag's closure system. A proper seal is vital to maintain a controlled environment for the stored items. Look for options that offer heat sealing or zip-lock closures, which can help prevent moisture and contaminants from entering while providing an adequate barrier against static charges. Additionally, it's important to consider the bag's transparency. Clear bags allow for easy identification of contents, streamlining inventory management and reducing handling time. By focusing on these key attributes, you can make an informed decision that aligns with your specific needs for ESD protection.

| Feature | Description | Recommended Use |

|---|---|---|

| Material | Typically made from polyethylene or other conductive materials to reduce static. | Storing electronic components, PCBs (printed circuit boards). |

| Thickness | Measured in mils; thicker bags provide more protection against damage. | Shipping delicate parts, in-field repairs. |

| Size Options | Available in various sizes to accommodate different components. | Custom packaging, bulk component storage. |

| Closure Type | Zipper, heat seal, or self-adhesive closures for secure sealing. | Long-term storage, shipping. |

| Static Protection Level | May include certifications for static protection based on industry standards. | High-end electronics, sensitive instruments. |

| Color | Color coding helps in identifying contents easily. | Inventory management. |

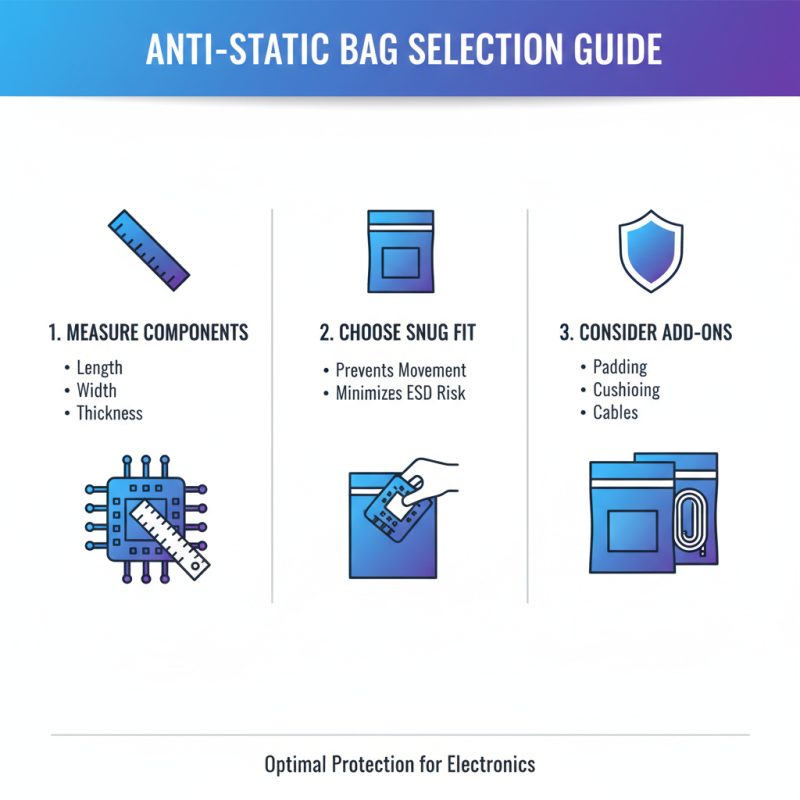

When selecting the right anti-static bag for your needs, determining the appropriate size is crucial for ensuring optimal protection for your electronic components. Anti-static bags come in a variety of sizes, and choosing one that fits your item snugly not only prevents movement during transport but also minimizes the risk of electrostatic discharge (ESD). To gauge the correct dimensions, measure your components carefully and consider both their length and width, accounting for any additional padding or cushioning you might require.

It's also essential to consider the type of components you will be storing in the bags. For smaller components, like chips or resistors, smaller bags may suffice. However, larger items, such as circuit boards or entire devices, will require more spacious bags to accommodate their dimensions without excessive folding or bending, which could otherwise compromise their integrity. Evaluating your inventory and predicting future needs can further guide you in selecting a size that balances versatility and protection for varying items over time.

Anti-static bags are essential tools across various industries, particularly in electronics and manufacturing, where the prevention of electrostatic discharge (ESD) is critical. In the electronics sector, these bags are commonly used to store and transport sensitive components such as circuit boards, semiconductors, and other delicate devices. By providing a controlled environment that dissipates static electricity, anti-static bags help ensure that these components remain functional and are not damaged during handling or transit.

In addition to electronics, anti-static bags also find significant applications in the pharmaceutical and medical industries. Here, they are used to protect sensitive equipment and materials that can be adversely affected by static electricity. For instance, packaging for diagnostic tools and delicate medical devices often utilizes anti-static materials to safeguard their reliability and longevity. Furthermore, the automotive industry employs these bags to protect electronic parts that are integral to modern vehicles, minimizing the risk of damage that could arise from electrostatic buildup. Overall, anti-static bags play a crucial role in maintaining the integrity of products across various sectors.

When it comes to storing sensitive electronic components, using anti-static bags is crucial to prevent damage from static electricity. However, simply having the bags isn’t enough. Proper storage and handling are essential to maintain their effectiveness. One important tip is to store anti-static bags in a cool, dry environment. Excessive heat or humidity can degrade the bag's protective properties, rendering it ineffective.

Another vital aspect of handling anti-static bags is to avoid unnecessary contact with surfaces that could create static. Always ensure that you are grounded before handling the bags or the components inside them. This can be easily achieved by using wrist straps or ESD (electrostatic discharge) mats. Additionally, be cautious when sealing bags; using tape or adhesives not specifically designed for anti-static use could compromise their anti-static capabilities.

Finally, when transporting or relocating items stored in anti-static bags, make sure they are secured properly to avoid movement that could generate static electricity. It is advisable to use ESD-safe containers for transport as well, ensuring that the bags remain protected during transit. Keeping these tips in mind can significantly enhance the longevity and effectiveness of anti-static bags in safeguarding your electronic components.

This chart illustrates the importance of proper storage and handling of anti-static bags. The data represents the percentage of users significantly affected by various factors when selecting anti-static bags for their needs.

Interested in working with our team? Reach out to our team for a no-strings-attached consultation.

1 (833) PPC-FLEX

1111 Busch Pkwy

Buffalo Grove, IL 60089, USA