In the world of packaging, the choice of materials is crucial. Shrink film stands out as a versatile option. This film wraps around products tightly when heat is applied. It provides a protective layer against dust, moisture, and handling damage. Many businesses favor shrink film for its efficiency and cost-effectiveness.

However, navigating the various options can be overwhelming. There are many types of shrink film available, each with unique properties. Some films are designed for retail displays, while others offer thermal insulation for food items. It's essential to choose the right type based on your packaging needs.

Reflecting on these choices is important. Often, factors like environmental impact and storage conditions are overlooked. Brands may rush into decisions without considering long-term effects. Therefore, exploring the 2026 best shrink film options can help refine your packaging strategy. With the right insights, businesses can enhance product presentation and protection.

Shrink films have become essential for packaging and protection in various industries. Understanding the materials used can enhance your choices. Polyolefin and PVC are the most common types. Polyolefin is known for its versatility and clarity. PVC offers durability but may not suit all products. Evaluating their properties helps in selecting the right type for your needs.

When choosing shrink film, consider thickness and width. Thicker films provide enhanced protection. However, they may be harder to shrink evenly. The width should also match your product dimensions. This ensures a snug fit. A misfit can lead to unsightly packaging and waste.

Tips: Always test the shrink film with your equipment. Not all films work well together. Adjust settings for optimal results. Keep extra film on hand for unexpected projects. Mistakes happen, and it’s good to be prepared. Experiment with different materials to see what works best for your products.

When choosing shrink film for packaging, several factors are essential. The type of product being packaged plays a vital role. Products with irregular shapes may require specialized film. A study by Smithers Pira indicates that the global shrink film market is expected to reach $6.66 billion by 2026, highlighting the growing importance of this packaging method.

Another key factor is the thickness of the film. Thicker films offer better durability but may add weight. This can impact shipping costs. On the other hand, thinner films can save on material costs, yet might not provide the same level of protection. Evaluate your priorities carefully.

Tips: Always test the film in real-world conditions. A trial run can reveal potential flaws. Additionally, environmental impact is increasingly crucial. Films made from sustainable materials can appeal to eco-conscious consumers. Be aware of certifications and their implications.

Ultimately, the right shrink film balances protection, cost, and sustainability. It's also useful to adapt based on customer feedback. What seems best on paper might not always perform in practice.

| Shrink Film Type | Material | Thickness (Microns) | Applications | Key Features |

|---|---|---|---|---|

| Polyolefin Shrink Film | Polyethylene/Polypropylene | 15-75 | Food Packaging, Gift Wrapping | High clarity, Strong seal, FDA compliant |

| PVC Shrink Film | Polyvinyl Chloride | 25-100 | Beverage Bottles, Electronics | Cost-effective, Good for non-food items |

| PE Shrink Film | Polyethylene | 50-150 | Industrial Packaging, Palletizing | Excellent stretchability, Durable |

| PLA Shrink Film | Polylactic Acid | 20-80 | Eco-friendly Packaging, Retail | Biodegradable, High clarity |

| Cross-Linked Shrink Film | Cross-Linked Polyethylene | 50-120 | Heavy-duty Packaging, Automotive Parts | Superior strength, High temperature resistance |

Choosing the right shrink film can make a significant difference in packaging and protection. In 2026, several options stand out for their effectiveness and versatility. Many users appreciate films that offer clarity and durability. Clear shrink films allow products to be seen clearly, enhancing customer appeal. A well-packaged item creates a strong first impression.

Different films cater to various needs. Some are designed for machine use, while others are more suitable for manual applications. Be aware that not all films stick properly upon application. This can result in damages, which makes it essential to test different types. Certain films may not perform well in extreme temperatures, causing them to warp or rip easily.

Thickness is another important aspect to consider. Thinner films can be cost-effective but may lack strength. Users often find themselves needing to use double layers, which raises expenses. Conversely, thicker films provide security but may be more challenging to handle. Balancing price with performance can lead to better choices. Always think deeply about what each option brings to the table.

Shrink film offers versatile solutions across various industries. It is used in packaging to provide protection and improve presentation. Products like food, electronics, and toys often benefit from shrink wrap. The tight sealing prevents damage and contamination, which is essential in many sectors.

For food packaging, shrink film helps maintain freshness. It can extend shelf life by protecting against moisture and air. In the electronics industry, shrink film shields sensitive components from dust and static electricity. However, some manufacturers overlook the importance of proper sealing techniques. Poorly sealed products may lead to spoilage or malfunction.

Tips: Always test your sealing method. Improper sealing can lead to product failure. Experiment with different temperatures for optimal results. It's crucial to find the right balance between heat and duration. Keep in mind that the thickness of the film matters. Thicker films may offer better protection, but they also require different application techniques.

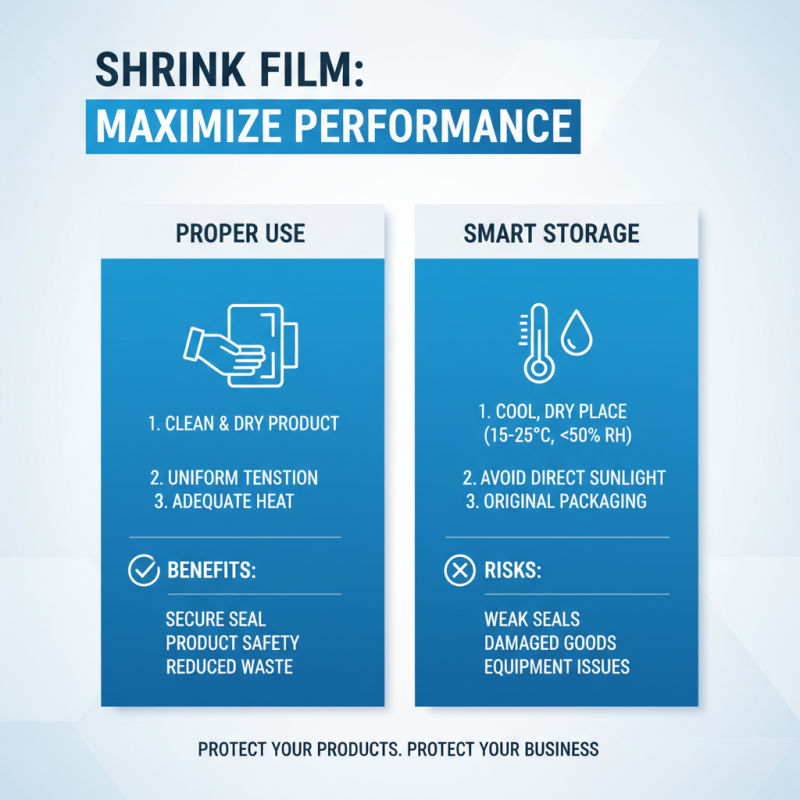

Shrink film is essential for packaging and protection, but its proper use and storage can greatly affect performance. According to industry data, improper handling can lead to reduced effectiveness, impacting product safety. Stored in high humidity or extreme temperatures, shrink film can lose its sealing properties.

Using the right tools is also critical. A heat gun or tunnel ensures even shrinking, which can improve the appearance of the final product. However, many overlook this. The average shrinkage rate varies from 40% to 70%, depending on the film type used. It's essential to check specifications. Moreover, cutting the film too large can waste material and increase costs.

When storing shrink film, it's best to keep it in a cool, dry place. Avoid exposure to direct sunlight. This can degrade the film integrity and affect its protective qualities. Regularly inspect stored rolls for any signs of damage. Thoughtful handling and proper storage can prevent setbacks and ensure better results.

Interested in working with our team? Reach out to our team for a no-strings-attached consultation.

1 (833) PPC-FLEX

1111 Busch Pkwy

Buffalo Grove, IL 60089, USA