The industry of plastic bag manufacturers plays a crucial role in the global packaging sector. According to a recent report by Smithers Pira, the plastic bag market is projected to reach $14 billion by 2025, highlighting its substantial demand. Plastic bags are essential for numerous businesses, from retail to food services.

Expert James Turner, a notable figure in packaging research, stated, "Plastic bags offer essential convenience, but sustainability remains a pressing challenge." His observation underscores the tension within this industry. While plastic bags are favored for their lightweight and durability, they contribute significantly to environmental concerns. Over 1 trillion plastic bags are used annually, emphasizing the need for responsible production and disposal.

Many plastic bag manufacturers face scrutiny regarding their environmental impact. As governments implement stricter regulations, manufacturers must innovate. The balance between convenience and environmental responsibility is delicate. Reflecting on industry practices can lead to sustainable solutions. Manufacturers need to adapt to remain relevant while addressing ecological pressures.

A plastic bag manufacturer creates various types of plastic bags used in multiple industries. These bags can serve many purposes, from carrying groceries to packaging products. The production process typically involves melting plastic pellets and shaping them into bags. Manual labor and technology often work hand in hand during this process. Workers monitor machines while adhering to safety protocols.

While efficiency is important, the industry faces challenges. Plastic waste and environmental concerns are at the forefront. Many consumers are becoming more conscious of the impact of plastic. This awareness has led to discussions about sustainability and alternatives. Manufacturers are now exploring biodegradable options. Such shifts can be complex and require significant investment.

Moreover, the market is highly competitive. Price pressures can lead to cost-cutting measures that might impact quality. Not all manufacturers adhere to the same standards. Quality control remains a concern in many facilities. As the industry evolves, manufacturers must reflect on their practices and adapt to meet both consumer demands and environmental responsibilities.

Plastic bag manufacturers play a crucial role in the supply chain. They produce bags used in various sectors, including retail, agriculture, and food services. According to the Flexible Packaging Association, the flexible packaging market, which includes plastic bags, was valued at approximately $32 billion in 2020 and is projected to grow steadily.

Manufacturers typically source resin, a key raw material, from petrochemical companies. They then convert this resin into bags through processes like extrusion and thermoforming. The efficiency of these processes impacts production costs and lead times. However, the environmental challenges tied to plastic waste have raised questions about sustainability. Many manufacturers are now exploring biodegradable and recyclable alternatives.

Despite advancements, the industry faces hurdles. Recycling rates for plastic bags remain low, often below 10%. This raises the need for greater consumer awareness and improved recycling systems. The reliance on disposable products also presents a critical reflection point. The future of plastic bag manufacturing may depend on innovation and a shift towards sustainable practices.

| Manufacturing Process Step | Description | Key Materials Used | Equipment Needed |

|---|---|---|---|

| Polymer Production | Creating polyethylene from petrochemical feedstocks. | Ethylene, polymer additives | Reactor, heat exchangers |

| Film Extrusion | Heating and forcing polymer through a die to create film. | Extruded polyethylene film | Extruder, die, cooling rollers |

| Printing | Adding designs or logos onto the film surface. | Ink, solvents | Flexographic printers, drying units |

| Bag Conversion | Cutting and sealing film to create bags of various dimensions. | Polyethylene film | Bag-making machines, heat sealers |

| Quality Control | Testing finished bags for durability, thickness, and defects. | N/A | Testing equipment, gauges |

Plastic bags are produced using a variety of materials that impact their quality and sustainability. Polyethylene is the most common material, known for its flexibility and durability. It comes in different forms, such as low-density (LDPE) and high-density (HDPE), each serving specific purposes. Other materials like biodegradable plastics are emerging, aimed at reducing environmental impact.

When sourcing materials, manufacturers need to consider data trends. Recyclable options are becoming more popular as consumers demand eco-friendly products. For instance, recycled polyethylene is gaining traction. This shift challenges manufacturers to innovate while meeting market demands.

Tips: Always stay updated on new materials. Attend trade shows to see innovations firsthand. Collaborate with suppliers for sustainable options. Understanding your material options is crucial for production.

Mindful production processes are essential. Balancing cost and sustainability can be difficult. Often, manufacturers face pressure to lower prices. This can lead to compromises in material quality. Reflecting on production choices is vital for long-term success.

Plastic bag manufacturing begins with resin. Resin is a polymer that forms the basis of plastic. It comes in large pellets. These pellets make their way into industrial machines designed for processing.

The manufacturing process involves heating the resin until it melts. This molten material can be shaped into bags using extrusion. During extrusion, a die gives the desired shape. It’s essential to control temperatures and speeds carefully. A slight error can lead to defects.

Once the bags are formed, they undergo cooling. This step solidifies them into usable products. Sometimes, manufacturers add colors or prints during this phase. Quality control is critical throughout. Small flaws can hinder a batch’s effectiveness. These processes require attention and precision, yet variations can disrupt consistency, prompting reflection on manufacturing practices.

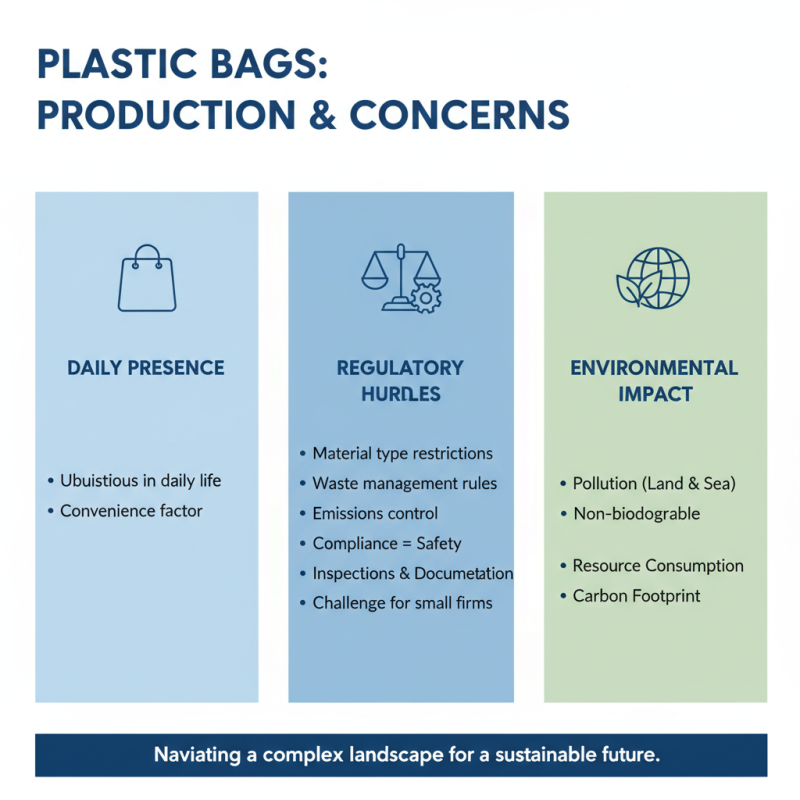

Plastic bags are prevalent in our daily lives, but their production raises significant regulatory and environmental concerns. Manufacturers must navigate a complex landscape of regulations. These rules often govern materials used, waste management, and emissions produced during manufacturing. Compliance ensures safety, yet can be challenging for smaller firms. Regular inspections and documentation are mandatory, adding layers of bureaucracy.

The environmental impact of plastic bags is profound. They contribute to pollution and wildlife harm. Millions are discarded every day, ending up in landfills and oceans. A single plastic bag can take centuries to decompose. This delay leads to severe long-term consequences for ecosystems. Manufacturers are now encouraged to explore biodegradable options, though these are not free from criticism.

Nonetheless, the shifts towards sustainability are slow. Many companies still prioritize cost over eco-friendliness. Consumer awareness is rising, but habits change slowly. Awareness campaigns often struggle to instill significant shifts in behavior. The journey toward reducing plastic bag use is ongoing, with many questions still unanswered. What will the future hold?

Interested in working with our team? Reach out to our team for a no-strings-attached consultation.

1 (833) PPC-FLEX

1111 Busch Pkwy

Buffalo Grove, IL 60089, USA