Shrink wrap is a versatile packaging material widely used in various industries. It consists of a plastic film that shrinks tightly around products when heat is applied. This creates a secure and protective layer. Many businesses use shrink wrap to bundle items. It ensures products remain intact during shipping and handling.

Many popular uses of shrink wrap include packaging food, electronics, and books. For example, a stacked group of items can be held together without shifting. This gives added stability. However, while shrink wrap is effective, it is not without drawbacks. The process often generates plastic waste. Many companies struggle with eco-friendly alternatives.

Understanding shrink wrap and its applications can lead to more efficient packaging solutions. It is crucial to recognize the balance between convenience and environmental impact.

Shrink wrap is a versatile packaging material that is used across various industries. It is made of plastic film that shrinks tightly over products when heat is applied. This process ensures a secure fit around the item, protecting it from moisture, dust, and tampering. The global shrink film market size was valued at approximately $10 billion in 2020, with projections indicating a potential growth rate of 4.5% annually through 2027.

The primary function of shrink wrap is to bundle and protect products. It is commonly used in food packaging, electronics, and pharmaceuticals. The clear visibility of the product through the wrap is a significant advantage. However, there are concerns about environmental impact. While shrink wrap provides excellent protection, it is typically made from non-biodegradable materials. Manufacturers are exploring eco-friendly alternatives, but the transition is slow.

Tips: When using shrink wrap, ensure the correct heat settings to prevent burning. Test your wrapping technique with various products. Keep in mind that not all shrink films perform equally under different conditions. For best results, choose a film suitable for your specific product type.

Shrink wrap is a versatile packaging solution, commonly used across various industries. Its effectiveness relies heavily on the materials used. The most prevalent types include polyethylene (PE), polyvinyl chloride (PVC), and polypropylene (PP). Each material has unique properties that cater to different packaging needs.

Polyethylene is the most widely used shrink wrap. It is notable for its excellent clarity and strength. According to industry reports, around 50% of shrink wraps use polyethylene due to its cost-effectiveness. PE is also recyclable, which appeals to eco-conscious consumers. In contrast, PVC shrink wrap offers superior stretchability and conformability. However, it is less environmentally friendly, which raises concerns in today’s market.

Propylene is often favored for products requiring heat resistance and durability. Its high melting point makes it suitable for applications involving hot items. Nonetheless, this material can be more expensive than its counterparts. The decision about which material to use often involves a trade-off between cost and performance. Many companies still struggle to find the perfect balance between sustainability and effectiveness. The evolving landscape of packaging requires ongoing reflection and adaptation.

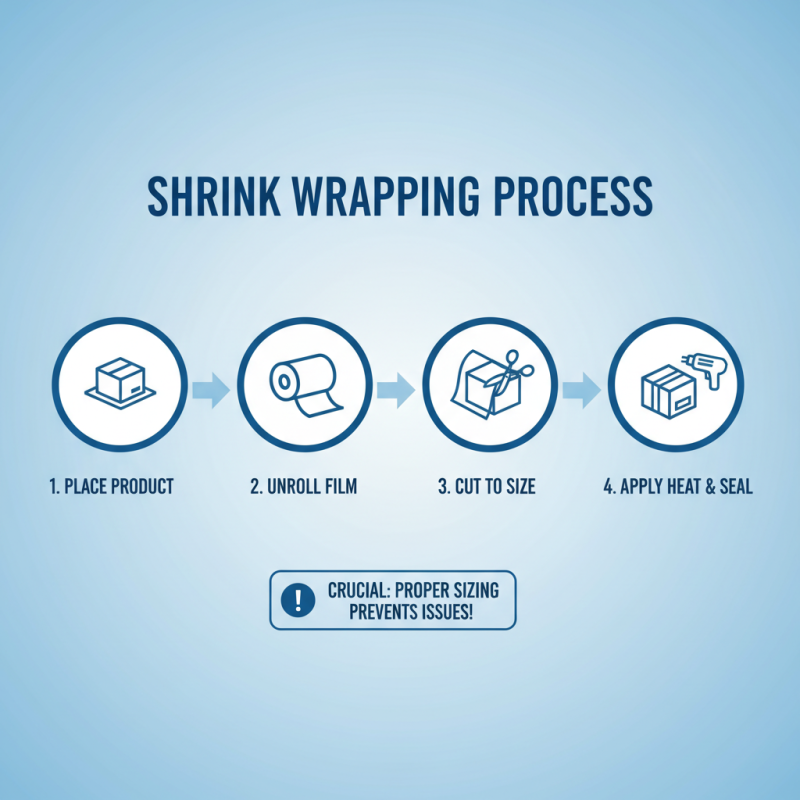

The shrink wrapping process is simple yet effective. It starts with placing the product on a flat surface. A roll of shrink film is then laid out. Cut the film according to the size of the product. This step is crucial; too big or too small can lead to issues.

Next, wrap the film tightly around the product. Make sure there are no air gaps. Use a heat sealer to create a tight seal. Double-check if the seal is secure; loose ends can cause wrinkles. After sealing, the wrapped product should go through a heat tunnel. The heat will shrink the film tightly around it.

Sometimes, mistakes happen during this process. The film can be uneven or the seals may break. These faults can lead to damaged products. Take time to inspect each wrapped item. It’s important to ensure quality. Adjustments may be needed in the wrapping technique. Consistent practice helps improve results over time.

Shrink wrap is a versatile packaging material widely used across various industries. Its primary application is to secure items for shipping and storage. According to a report by MarketsandMarkets, the global shrink wrap market is expected to grow to over $11 billion by 2025. This rise is driven by increasing demand in sectors like food and beverage, electronics, and consumer goods.

Common applications include bundling products together. For instance, multiple bottles may be wrapped to reduce shifting during transport. Another application is in food packaging, where shrink wrap keeps products fresher for longer. The film creates an airtight seal. This reduces spoilage, which is critical in the food industry. Studies show that shrink wrap can extend the shelf life of packaged goods by up to 25%.

**Tip:** When using shrink wrap, ensure the heat source is consistent. Inconsistencies can lead to weak seals, which compromise product integrity.

Shrink wrap is also used for protecting items from dust and moisture. This is particularly relevant in storage and transportation. However, not all shrink films are created equal. Some may not withstand extreme temperatures. Always consider the specific needs of your product before selecting the shrink film type.

**Tip:** Conduct a test run on how your shrink wrap reacts under different conditions. This will help identify and mitigate potential issues before your product reaches the market.

Shrink wrap is a versatile packaging solution that offers significant benefits in product protection and presentation. Its ability to conform tightly around various products minimizes physical damage during transit. This ensures that goods arrive at their destination in pristine condition. The shrink-wrap material is lightweight, reducing shipping costs while still providing Robust protection against dust, moisture, and tampering.

Presentation is another essential aspect of shrink wrap. Products wrapped in this material look neat and appealing. It enhances the visual aspect, making them more attractive to consumers. However, one must consider the environmental impact of shrink wrap materials. While they offer numerous advantages, the reliance on plastic can be a concern. Exploring biodegradable options could be a step forward. Adopting shrink wrap requires a balance between aesthetics and sustainability.

Interested in working with our team? Reach out to our team for a no-strings-attached consultation.

1 (833) PPC-FLEX

1111 Busch Pkwy

Buffalo Grove, IL 60089, USA